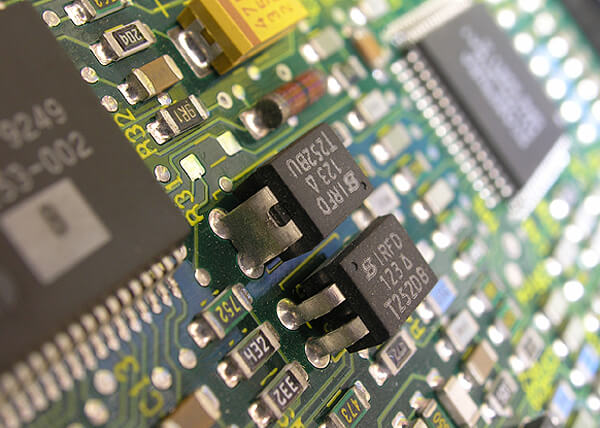

PRINTED CIRCUIT BOARD (PCB) ASSEMBLY SERVICES

At RPC Electronics, we are printed circuit board assembly specialists and can provide immediate response to your most challenging requirements. We offer PCB assembly of single or multi-layer flexible or rigid circuit boards, and are equipped to handle a high mix of features with varied complexity. Our facility houses equipment ranging from automated pick-and-place equipment and large scale wave soldering ovens to hand insertion and soldering stations. These diverse capabilities enable us to meet volume demands ranging from quick turnaround prototypes to just-in-time deliveries of high quantity production runs. Conformal coatings are also available to meet environmental requirements.

Our quality management program is a cornerstone of our operation, and our workmanship conforms to IPC 610 and ISO 9002 standards for thru hole, hybrid, and surface mount PCBs. We have engineers on staff to assist you with design and layout, and also offer a complete component sourcing and inventory management program. When you choose our PCB assembly service, you are guaranteed consistent and timely delivery of your valued circuit board assemblies.

Contact us today to learn about how the extent of our offerings can help meet your dynamic business needs.

PROJECTS

Learn about our accomplished projects associated with this capability

Assembly of a Printed Circuit Board (PCB) For an Instrumentation Application

A printed circuit board was required for an instrumentation application, and RPC Electronics was contracted to perform the custom fabrication due to our experience and expertise. The board as…..

Assembly of a Printed Circuit Board (PCB) For a Network Communication Application

A customer in the network communications industry needed a company with the experience and resources to assemble their printed circuit board to exacting specifications. RPC Electronics was…..

PRINTED CIRCUIT BOARD (PCB)

ASSEMBLY CAPABILITIES

Printed Circuit Board Assembly General Capabilities

Just-In-Time, Prototypes, Quick Turnaround Prototypes

Circuit Board Construction

- Combined Construction (Rigid and Flex)

- Copper Clad

- Double-Sided

- Etched

- Exotic

- Solder Mask Over Bare Copper (SMOBC)

- Surface Mount

- Flexible

- Metal Core Insulated

- Mixed Technology (SMT and Thru Hole)

- Molded 3D

- Multilayer

- Plated-Through-Hole (PTH)

- Silver Through Hole

- Single-Sided

Materials

- Fiberglass

- FR-4

- Getek

- Kevlar

- Mylar

- Phenolic

- Polyester

- Polyimide

Number of Board Layers

2 to 14 Layers

Circuit Board Features

- Fine Line

- Flush Surface

- Lead Free

- PCI

- Plug-In

- Surface Mount

- Thru Hole

- Micro BGA

- Rigid-Flex

- Single Sided

- Double Sided

- Circuit Board to Box

- Conformal Coating

- Fine Pitch

Assembly Methods

- Automated Assembly

- Hand Insertion

- Hand Soldering

- Point-to-Point Wiring

- Reflow

- Wave Solder

- Wire Wrapping

Additional Services Provided

- Board Fabrication

- Burn-In

- Component Programming

- Component Sourcing

- Conformal Coating

- Contract Manufacturing

- Cutting

- Design

- Inspection

- Layout

- Plating

- Potting

- Repair

- Rework

- Routing

- Stamping

- Reflow

- Wave Solder

- Wire Wrapping

Turnaround Time

Component Dependent

Industry Focus

- O.E.M Industrial

- Instrumentation

- Electronics

- Industrial Automation

- Medical

- Telecommunications

Production Volume

Component Dependent

Industry Focus

IPC

Originally Institute for Interconnecting and Packaging Integrated Circuits,

now called IPC. These are standards for printed circuit board

design and manufacturing.

ISO

International Organization for Standardization

Download a printable version of this capability

READY TO GET YOUR FREE QUOTE?

Send us your requirements and we will work together to help make your project a reality.