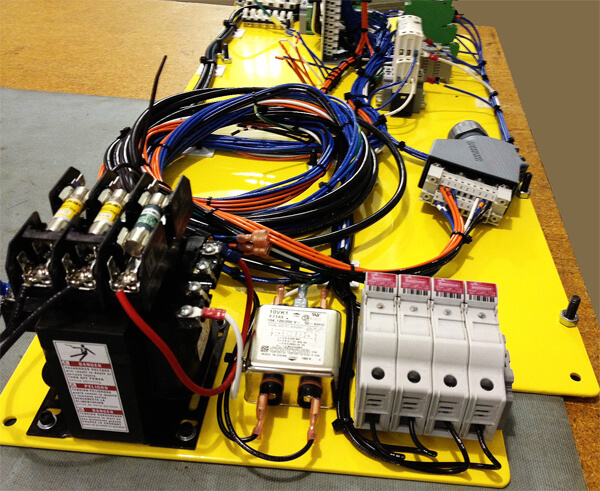

ELECTROMECHANICAL ASSEMBLY OF A PANEL USED WITHIN AN INDUSTRIAL AUTOMATION APPLICATION

RPC Electronics was commissioned to produce the panel highlighted here for a customer in the industrial automation industry, for use in a full scale automation system application to meet the specified 2’ by 3’ size envelope. The components were laid out and assembled as determined by customer specifications, wires cut and marked as required, then connected with the integrated fuse and terminal blocks and circuit breakers. The entire unit was assembled, employing cutting and drilling procedures, and then subjected to accuracy and functionality testing employing point to point continuity testing methods.

The resulting unit is called a control panel, and turnaround time for this project was 2 to 3 weeks, shipped to the customer in Ohio. For more details about this electromechanical assembly, or our production range for custom cables as and our other capabilities please see the table below or contact us directly.

PROJECT HIGHLIGHT

Product Name

Electromechanical Assembly of a Panel

Capabilities Applied/Processes

-

Primary

- Metal Fabrication

- Wire Cutting & Marking

- Component Assembly

-

Secondary

- Cutting

- Drilling

Overall Part Dimensions

- Length: 3′

- Width: 2′

Components Used

- Fuse and Terminal Block/Circuit Breakers

In process testing/inspection performed

- Point to Point Continuity Testing

Industry for Use

- Industrial Automation

Delivery/Turnaround Time

- 2-3 Weeks

Delivery Location

- Ohio

Standards Met

- Customer Specifications

READY TO GET YOUR FREE QUOTE?

Send us your requirements and we will work together to help make your project a reality.